Gimme a high five

- hello9764

- Oct 25, 2017

- 3 min read

'Gimme a high five' is a interactive piece that was inspired by a recollection of my childhood days. High five is known as a gesture that would in some way, heightens the positive energy in someone. When I was young, I remembered growing up with my brother who was then, very mischievous, he often would ask me to give him a high five but intentionally give it a miss to make me feel miserable. I wanted to translate this etched memory of mine into something tangible, not with the intention to make others feel miserable, but to recreate part of my memory, which I find it amusing.

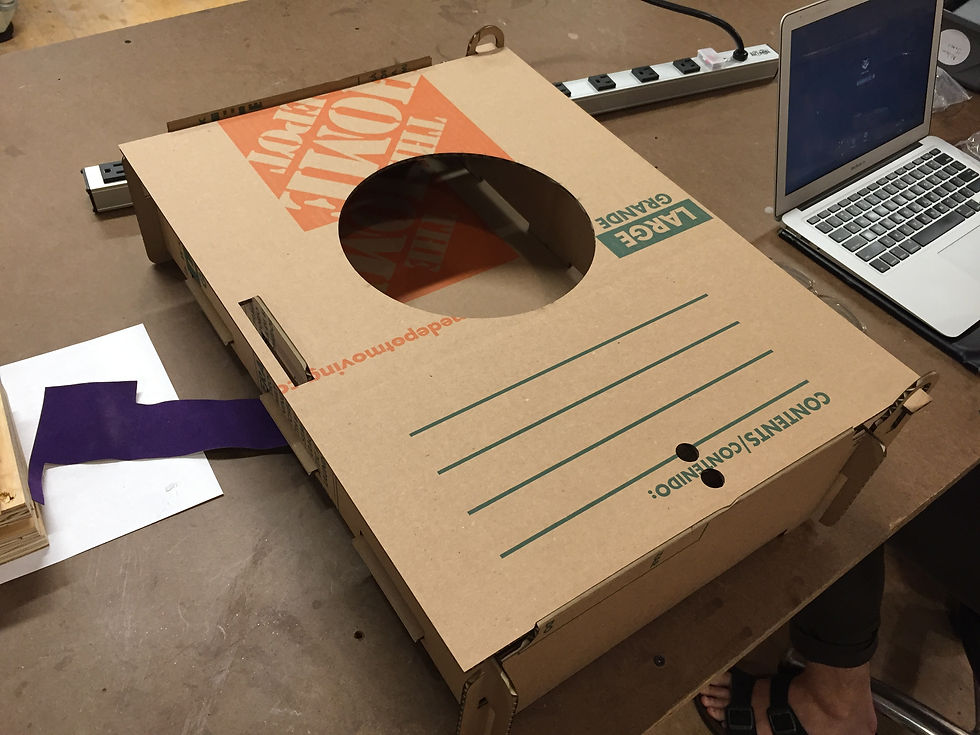

The interactive piece is made up different materials, the hand is made out of light materials, the enclosure is made out of cardboard. The mechanics of the piece involves two servo motors, a sensor and an LED screen. The LED screen will then read ‘You miss!’.

The execution

The interactive piece is a collaboration work with my team-mate Alden Jones whom, together, worked tirelessly on this project from conceptual, programming to the fabrication. Our strengths on different areas complemented well, and where we fall short on others, we make it up by doing our research and consultation.

We began sketching our ideas into paper and make sense of the work in its entirety. We were sensitive to the form of the work, how people would interact with it and the feedback that it would create. We wanted it to be in a form of a box, like jack in a box, our intention was to make it look fun, since halloween is around the corner, we were worried that it may look too morbid with just one hand sticking out.

The Issues

Issue 1

Because there was two movement for the hand, we thought of a possible D.I.Y method, however, with the amount of time given, we forgo the idea and used a two axis servo motor mount instead which helped tremendously.

Issue 2

Another issue I came about was the coding for the two servo motors, we used a digital output communication for the Arduino. I created a delay of 700ms each time presence is detected from the sensor, however, the delay was too long and I wanted it to happen rather instantaneously. I consulted the residence and he advised us to declare time as a variable rather than the delay. You can observe my codes here.

The logic behind the code for the servos is to make one of them move at at an angle of 180 constantly (servo 1), until presence is detected from the sensor, servo 1 would stop and servo 1 would move at angle 90. with minimal delay.

Issue 3

The servo's refused to work after we placed the two axis mount. It was working perfectly fine prior to us placing it on the mount, after changing the SG90 servo motors to the 360 TowerPro servo motors and testing it without a mount. Some of the ITP people said that it could be the power. We were advised to use a voltage regulator, and experiment using a 9V battery to run the servo separately, the power was still not strong enough. We resorted to use a 9V DC power supply instead and it worked perfectly fine.

The Fabrication

We created the box and had it laser cut to size.

We had two plans for the hand, one which was to create a piece out of plastic while the other was to cut it out using laser cutter. We chose to use the laser cutter option since it is presentable.

The Final Piece

Areas of improvement

After much deliberation and user testing, we have thought of a ways that we could further improve our work. We could add more sensors, any presences from the front would trigger the hand to move away, users would not be restricted to only one area. There could be a clearer indication of where to give a high five or to give a high five, (at the moment, there is only one sensor and a small LED at the front that says 'gimme a high five', it might not be visible to the audience). The hand could change direction as time goes by to lure audience to interact with the piece.

Comments